Tsubame Tsuiki Copperware

Produced in: Tsubame CityOn the wall at the back of the stairs on the first floor of THE NIIGATA, the "Niigata Manufacturing Collection" is exhibited, which features 10 types of manufacturing in Niigata.

This page introduces details about one of these, "Tsubame Tsuiki Copperware." In the actual exhibit, you can feel the breath of the maker through the materials, tools, and processes of each craft, so please take a look.

Tsuiki copperware is produced from a single copper sheet that is hammered into objects such as teapots and kettles. Repeated hammer blows produce a dense metal with a durable, beautiful surface. The copperware has variable coloring and patterns. That allure comes from the different look and feel from each workshop and artisan.

The assortment of products ranges from everyday household items such as tea sets, sake cups, and vases to works of art. It is delightful to watch as these creations change in appearance over time. With use, these items become more lustrous and alluring.

Unique techniques that developed from Japanese nails

The origin of this craft goes back to the production of wakugi nails, a side business farmers took up after flooding along the Shinano River long ago.

The production of tsuiki copperware began in the middle of the Edo period (1603-1867), when a copper mine was opened at Mt. Yahiko, near the city of Tsubame.

The artisans first focused on kettles as everyday household items, but in the Meiji period (1868-1912), they shifted to arts and crafts by incorporating carving techniques. In 1894, they even presented a vase to Emperor Meiji.

Today, Tsubame is the only place in Japan that produces tsuiki hammered copperware, which in 1981 was designated as a national traditional craft.

Magical handiwork by skilled artisans

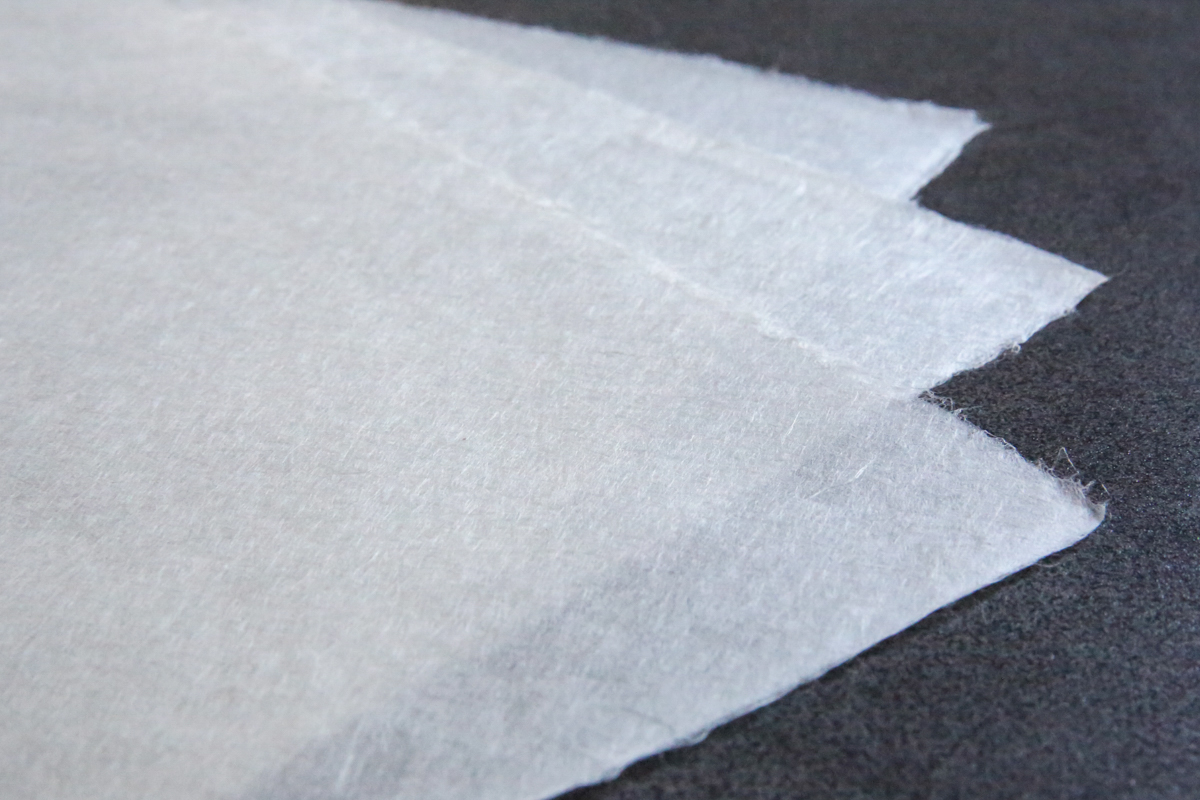

To shape an object, a single sheet of copper sheet is hammered to stretch or condense certain parts, and then. Heated to soften the metal. This process is repeated many times. After shaping, the surface is engraved and hammered with elaborate patterns, then lastly colored through use of a chemical reaction.

Many different tools are needed for these processes. For example, crafting a kettle involves using dozens of different toriguchi (iron bars) and hammers. It takes considerable time and effort by many artisans to create one of these copperware items by hand.